What is screen printing?

Introduction to screen printing

Before the discovery of paper, human beings used clay liquefied materials and plant mashed liquefied materials as materials to draw pictures and letters on flat rocks. According to the established theory, paper was invented by Cai Lun in the post-Han era of China at year 105, but it seems uncertain because the paper was discovered in the ruins of the pre-Han era. It was printed around the 7th century, and woodblock printing was the first printing.

Let's start with "What is printing?"

Printing refers to printing characters and pictures on a medium such as paper. Nowadays, it is commonplace to print photographs, etc., and it is now time to print not only on 2D but also on curved surfaces and complicated 3D media.

There are 4 main types of screens used for printing.

Letterpress printing

Put simply, it is a seal or print. Printing in which ink is applied to the letterpress and transferred is called letterpress.

Intaglio printing

Another name is gravure printing, which is the opposite of letterpress, and ink is applied to the recesses for transfer.

Planographic printing

Also known as offset printing, a special resin is thinly applied to a metal plate, and a film is attached to the part to be printed to transfer light. Apply ink to that part and transfer the ink to the rubber roller once. Then transfer the roller to paper.

Stencil printing

Make a hole in the part that want to print on the cloth-like part (formerly silk printing) that will be the screen, scrape the ink with a roller or squeegee, and transfer the ink from the hole part.

What is screen printing?

It is a printing method using a screen frame. The screen frame is made by weaving fibers such as stainless steel and polyester in a grid pattern. Just like a tennis or badminton net.

It is classified as "stencil printing" in which paste (functional material) is passed through the mesh of the screen frame and transferred to the substrate (object).

Current status of screen printing

It covers a wide range of fields, from printing letters and patterns on signboards and T-shirts to printing wiring for electronic devices.

In particular, while the technology called printed electronics is drawing attention, it is a construction method that is in increasing demand from the viewpoint of high productivity, low cost, and low environmental load.

Printed electronics refers to the use of printing technology to form electrical circuits and the like.

Printing technology is also used for the electronic devices around us and the small parts (sensors, boards, etc.) inside the smartphones you use.

Practice of screen printing

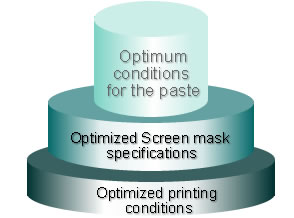

3conditions to realize optimum screen printing.

The setting of the optimum conditions for the paste is important.

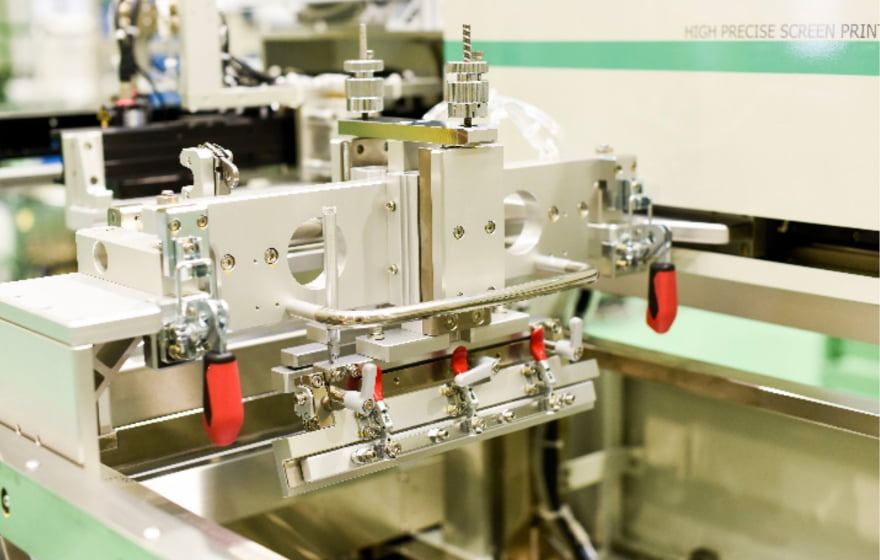

Optimized screen mask specifications

Optimized printing conditions by screen printing

Screen printing

Screen printing requires a paste, a screen, and a screen printer. The specifications of each of these items are shown below.

Paste

Type, ratios of filler, resin, solvent, additive, etc., viscosity

Screen

Silk gauze material, tension, type of silk gauze frame, bias

Screen printer

Type and hardness of squeegee, attack angle, clearance, squeegee and scraper speeds, pressure of printing

For better printing

What is most important for better printing is the rheology of the paste. Printing quality depends greatly on it.

The next important factor is the proper specifications of the screen mask.

Although the optimum paste and screen mask almost determine printing quality, there is one more requirement for better printing: the optimum printing conditions of the screen printer.

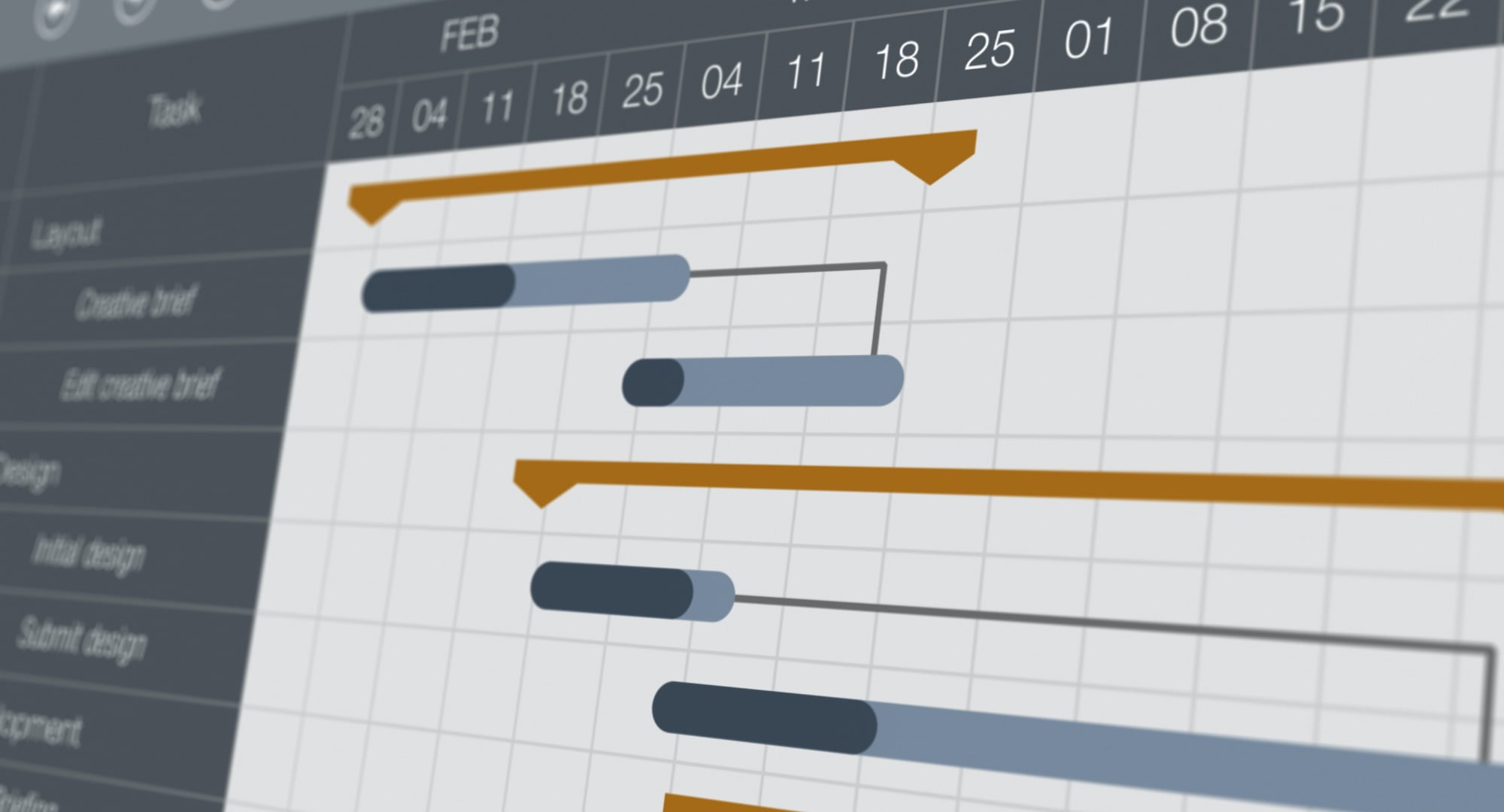

Lineup of Screen printer

Screen printer

MT-320 series

Printing area:150mm. It is a compact screen printer that has all the necessary functions. Supports small size printing with a print area of 150 mm or less. It is also ideal for research and development applications.

Screen printer

MT-650 series

Max. printing area: approx. 250mm (when use □550mm frame). It is a screen printer that is not only reliable but also easy to use. There are many options available, and it is compatible with various substrates such as green sheets and silicon wafers for solar cells.

Screen printer

MTP-1100 series

Max. printing area: approx. 550mm (when use □1100mm frame). It is a large single type standard screen printer. It is a screen printer that has both operability and quality even for large machines while increasing rigidity for large machines.

Screen printer

MTP-1300 series

Max. printing area: approx. 750mm (when use □1300mm frame). The MTP-1300 series is the largest screen printer among single type standard machines. As with the MT-650 series / MTP-1100 series, by adopting the original mechanism for the squeegee head driving unit and table driving unit, it is possible to maintain accuracy even with a large size.

Screen printer

Curved surface printer series

It is a machine that supports printing on curved substrates such as in-vehicle displays, instrument panels, and emblems. Micro-tec's unique mechanism allows you to freely print not only single concave surfaces and convex surfaces, but also S-shaped curved surfaces.

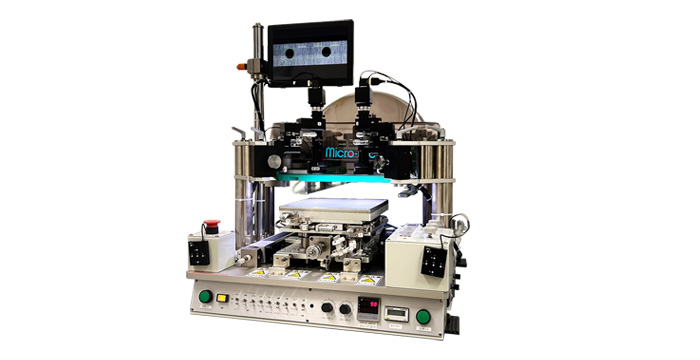

Laboratory screen printer

LABTOP 38

All (Compact, Excellent printability, Preciseness, Durability) in one high quality screen printer. Ideal size for laboratory use.

The

5 basic concept of Micro-tec.

Micro-tec’s original

Micro squeegee

- The ink discharge force can be stabilized at a fixed angle.

- It ensures higher printing accuracy under uniform pressure in combination with a low-pressure system.

Micro-tec’s original

Vertical float type air balance system

- With a printing system designed for printing pressure, images can be printed with a high degree of reproducibility, irrespective of the operator’s skills or capability.

- Images can be printed under appropriate printing pressure.

- The optimum printing conditions are available in combination with Micro Squeegee.

- High productivity: less burdens on the plate and the squeegee, enabling them to serve for many years to come.

The printing conditions can be set digitally.

The squeegee pressure, the flood blade pressure, and the back pressure can be individually set with the aid of a precision regulator and digital display.

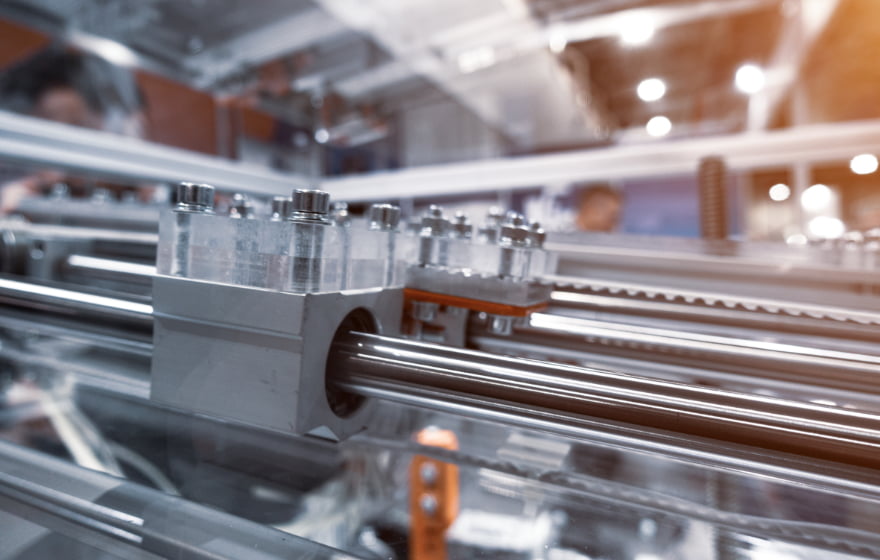

Low vibration

Adopted for squeegee travel is a linear travel mechanism comprising an AC servomotor and a steel belt (PAT・P), featuring low vibration and high linearity.

Highly rigid structure

To maintain the set optimum printing conditions and reduce the effect of the long secular change in machine accuracy on printing accuracy, the movement of the drive unit is minimized, and the printing plate frame is fastened to a highly rigid base supported by four columns.

4 mechanisms of screen printing

Four steps are carried out in screen printing.

Rolling・Discharge

Peel-off・Leveling

4 conditions for proper printing

POINT01

Attack angle

POINT02

Squeegee pressure

POINT03

Clearance

Screen / substrate / squeegee position

POINT04

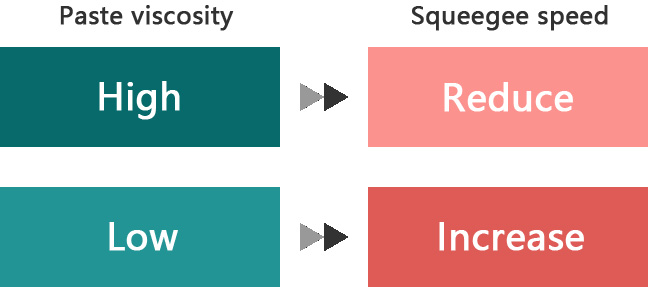

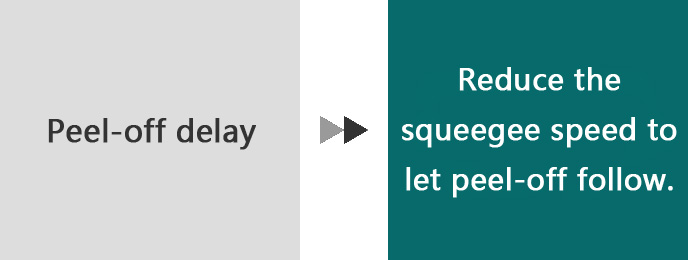

Squeegee speed

Relationship with paste viscosity

Relationship with peel-off

Ideas for realizing high-accuracy printing (summary)

- 1)Proper clearance

- 2)Quick peel-off: Use a high-tension plate.

- 3)igh-strength screen frame

- 4)Appropriate printing pressure

- 5)Stabilized squeegee travel

- 6)Rigidity and accuracy of printer:

Parallelism among the table, the squeegee, and the screen - 7)Working environment: Environmental control by temperature regulation

We accept various options and modifications

according to the application and budget.

Please feel free to contact us

about screen printing machines.