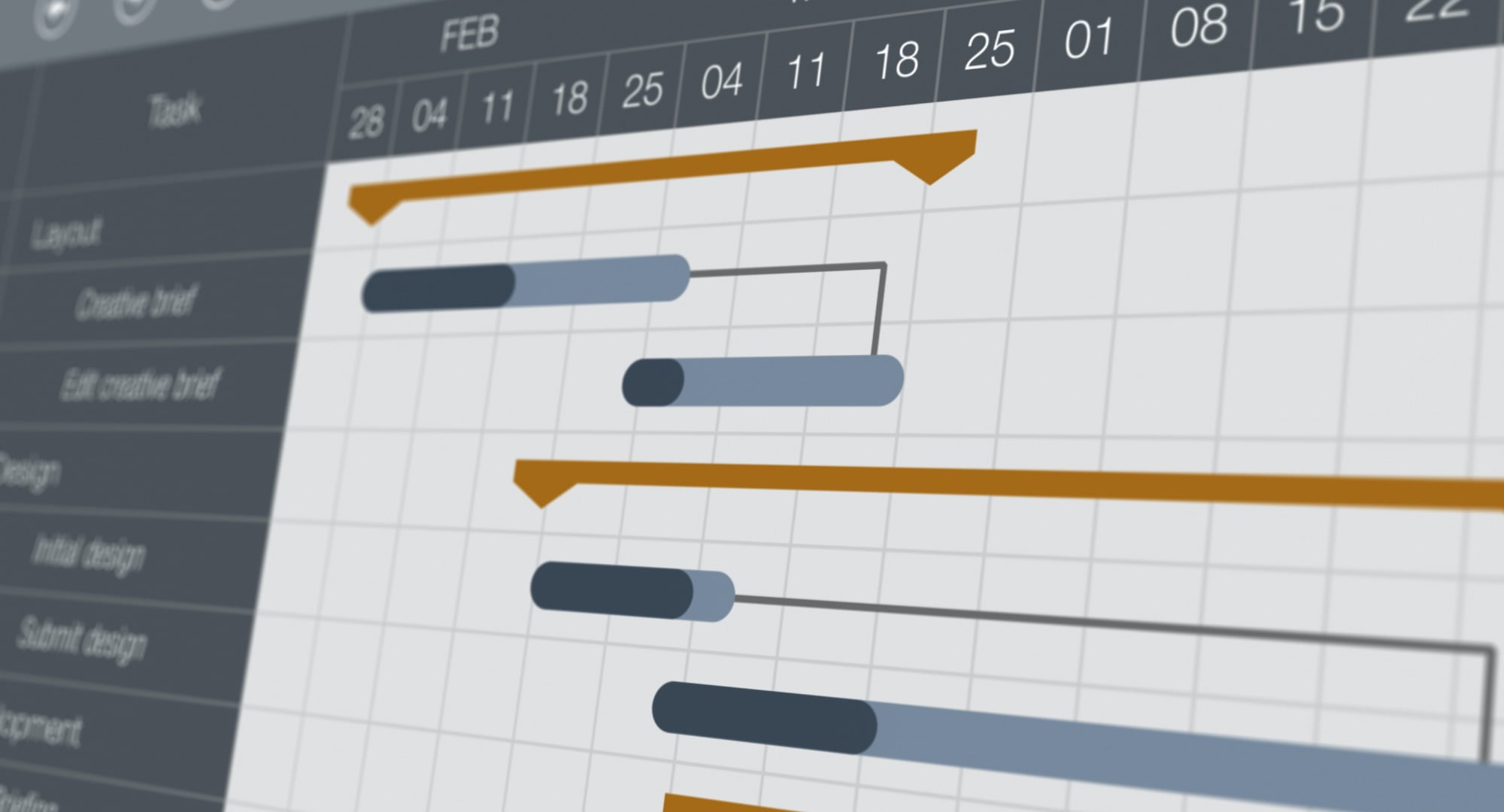

FA solution

Connect freely

Meet the needs of customers for "automation" and "efficiency".

High speed transfer line

High-speed transport of thin substrates.

Soft handling is possible even for thin and fragile substrates.

Multi-row transport line

The substrates are automatically aligned and transported in multiple rows.

The line length can be significantly reduced by multi-row transfer.

Loader / unloader (R to R)

A film substrate unwinding and winding unit.

The proper tension is automatically adjusted to transport the film.

There are also various options such as an edge controller, wrinkle removal mechanism, and protective film peeling mechanism.

Loader / unloader (substrates, sheets)

Take out the substrates one by one and transfer them to the next process. After processing, store it.

It can be used for many substrates such as ceramics, green sheets, glass, and films.

In addition, we can flexibly respond to customer requests such as for small and large substrates.

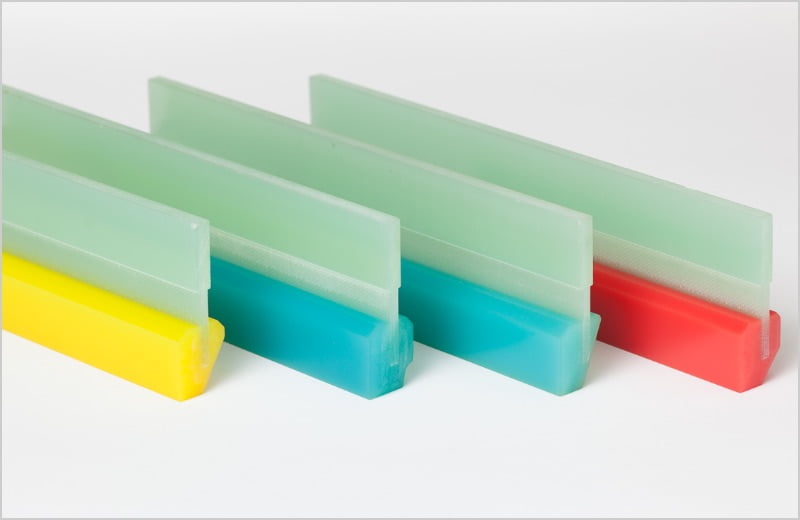

Various high speed sorters

The boards identified by the inspection unit are automatically sorted at high speed.

According to customer's request, it can be sorted in multiple stages such as color and quality. (Example: 48-step sort)

Automatic separator line

The protective film and sheet are peeled off without affecting the substrate.

Prevents uneven peeling due to human work.

Polishing equipment line

Automatically supplied the substrate. After that the surface of substrate will be polished with a polishing device, and then transported to the drying furnace.

Compatible with small to large substrates.

Inspection equipment (offline, inline)

Inspects and sorts the substrate before and after processing.

You can inspect a wide variety of products such as glass and film.

We accept various options and modifications

according to the application and budget.

Please feel free to contact us

about screen printing machines.