Screen printer optional items

Safety measure

Area sensor

When the sensor reacts to your hand or body, the device will stop immediately. We will propose products according to your safety specifications.

We can also handle light curtains according to the risk level.

Main air down sensor

It is a sensor that detects abnormalities when the supply of drive air, which is a utility for driving equipment, drops below a certain pressure.

Signal tower

An indicator light informs you of the operating status of the device. The usual option is a red / yellow / green three-color light with a buzzer.

Safety cover (Entire cover)

By enclosing the entire printing machine, you can prevent accidents such as accidentally pinching your hand in the drive unit. In addition, we will propose covers according to your needs such as side covers.

Exhaust flange

Mainly for odor control inside the entire cover, it can be installed upon request. Normally, it is installed near the bottom of the frame unit, but we can handle it in the desired position. It is also possible to have a damper on request.

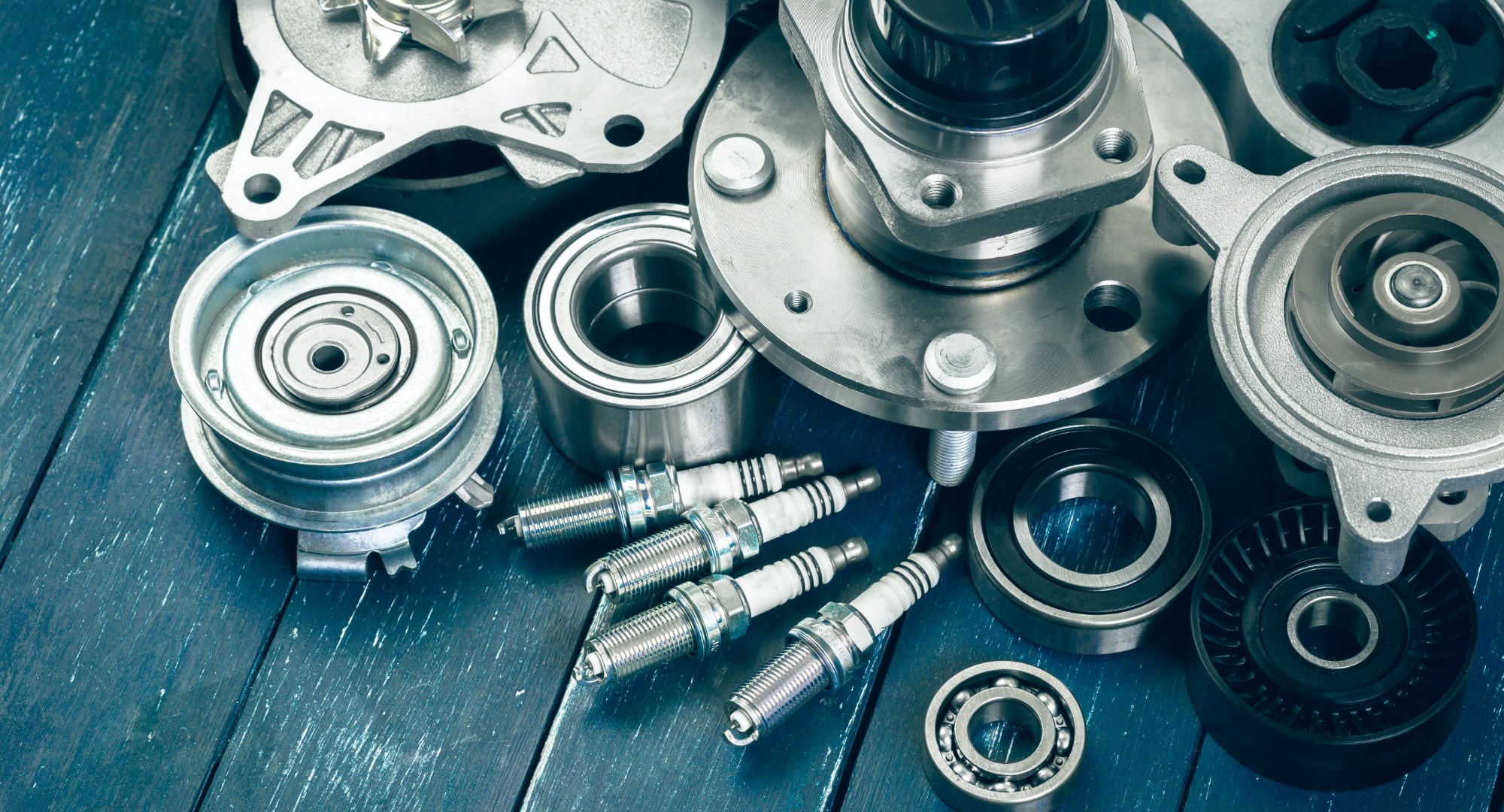

Squeegee head unit

Compatible with squeegees with holder

By setting the Micro squeegee and the flat squeegee in the squeegee holder of the same thickness, both squeegees can be attached to and detached from the squeegee unit.

Squeegee mounting air clamp

The squeegee is attached to and detached from the squeegee unit with an air clamp.

Double squeegee printing head

For printing that does not require paste coating with a flood blade, such as solder bump printing or fill-in-the-blank printing, attach two squeegees. One can be printed from the front to the back, and the other can be printed from the back to the front.

Pre-contact squeegee

It was confirmed that by pressing both ends of the screen immediately before the printing position on the main squeegee with pre-contact squeegees (PAT.). The screen and the substrate are in a band-like contact state, and bleeding can be significantly reduced. The screen is brought into contact with the board to create a contact print-like state, allowing natural plate release behind the main squeegee. Basic off-contact printing also gives good results.

Paste gathering squeegee

The paste that sticks out from the left and right sides of the printed squeegee during the squeegee stroke is returned to the printed squeegee range.

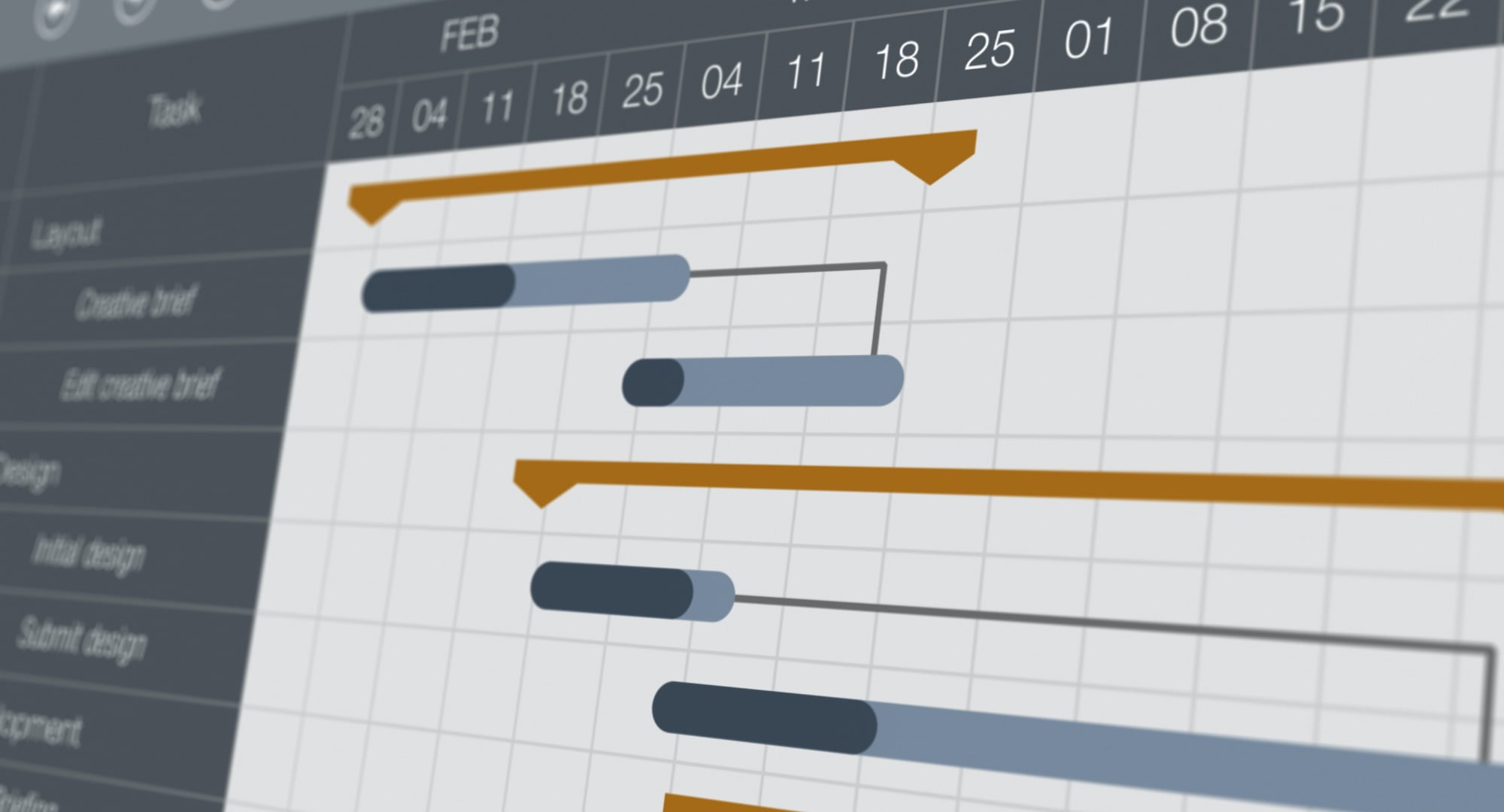

Automatic speed switching during squeegee stroke

The speed in the middle of the squeegee stroke can be changed as a response to the run-up area or the print pattern shape with respect to the print pattern area.

Squeegee automatic parallel adjustment

The left and right parallels of the printed squeegee are performed by the motor and load cell, and the squeegee and the table top surface are automatically parallelized. With automation, the time required for parallel adjustment can be shortened, greatly improving work efficiency.

Frame unit

Screen frame side XYθ adjustment

It makes it easy to align the substrate and frame. Operability can be expanded by making adjustments in combination with XYθ adjustment on the table side.

Frame attachment

It is a jig that allows you to set a small screen frame when you want to use a screen frame that is smaller than the specifications of the device.

Screen frame position deviation detection sensor

It is a sensor that confirms that the frame of the screen set in the device is set in the correct position.

Screen frame crack detection sensor

It is a sensor that detects the displacement of the frame when the frame set in the device is cracked.

Screen frame frontside peel-off mechanism

When the peel-off is poor in solid printing, push up one side of the screen frame according to the print stroke to separate the screen.

In the case of the printing method in which the peel-off after the print stroke, it is possible to set the push-up after the print stroke.

Table unit

Table slow descent (Z)

It is a mechanism that lowers the printing table at a very low speed. It is often used when using a metal mask or when performing on-contact printing. (When there is no gap between the frame and the substrate)

Slow stroke 0~10mm;Slow speed 0.01~10mm/sec(can be changed in 0.01 mm / sec units)

Porous jig

Due to its fine hole structure (ceramic material), it is used for suction fixing of thin substrates and fragile substrates (film-related, green sheet, etc.).

Through hole jig

A dedicated jig table for use in through-hole printing.

Paper-roll device

Used for fill-in-the-blank printing. It is a device to prevent the paste from adhering to the porous jig table by sandwiching clean paper between the substrate and the table.

Positioning clamp

Align the substrate with an automatic clamp. It is possible to support the two-sided standard and the center standard of the substrate.

Digging jig

A dedicated digging jig to eliminate the gap between the substrate and table and reduce damage to the screen frame.

Pin up/down mechanism

*Used for substrate alignment. Align the substrate with the rising pin on the printing table and position it.

*Used to lift the substrate to make it easier to remove the printed substrate.

Table LED

It is used as a mark for temporary alignment when the screen frame is attached.

Other options

Cleaning roller unit

It is a unit that uses the print table movement operation to attach dust to the slightly adhesive roller while the table is moving and remove the dust on the board.

Ionizer

It is mainly an anti-static measure that irradiates the substrate on the printing table with a static eliminator blow.

HEPA down blow

To keep the print area clean, install it according to the installation of the entire cover. Blow from the top of the entire cover.

Screen cleaning device

If symptoms such as bleeding appear during printing, it is common to wipe the back of the screen by hand and start printing again. The screen cleaning device is a device that automatically wipes the screen with a slight adhesive tape, which greatly improves work efficiency.

Foot switch

It is a start switch to improve work efficiency. The switch is placed on the floor to switch suction ON / OFF or use it for automatic start during printing.

Automatic paste supply device

It is a device that automatically supplies paste on a screen from a syringe that stores a certain amount of paste. You can set the supply timing according to the number of prints.

We accept various options and modifications

according to the application and budget.

Please feel free to contact us

about screen printing machines.