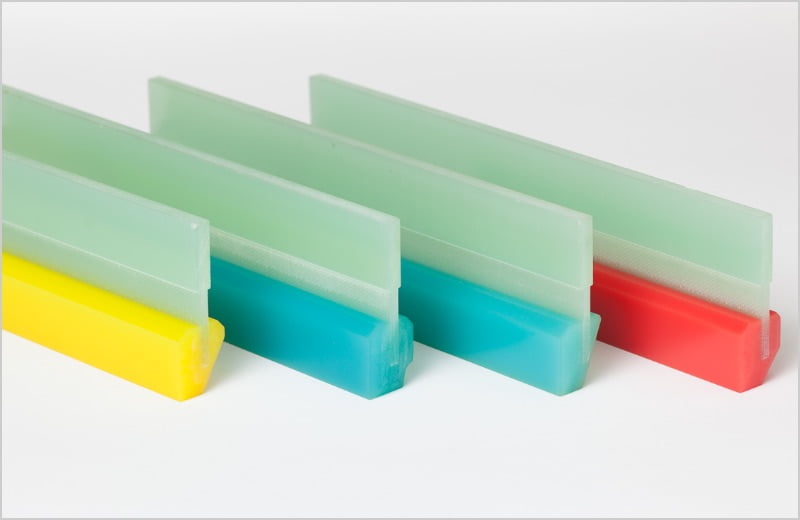

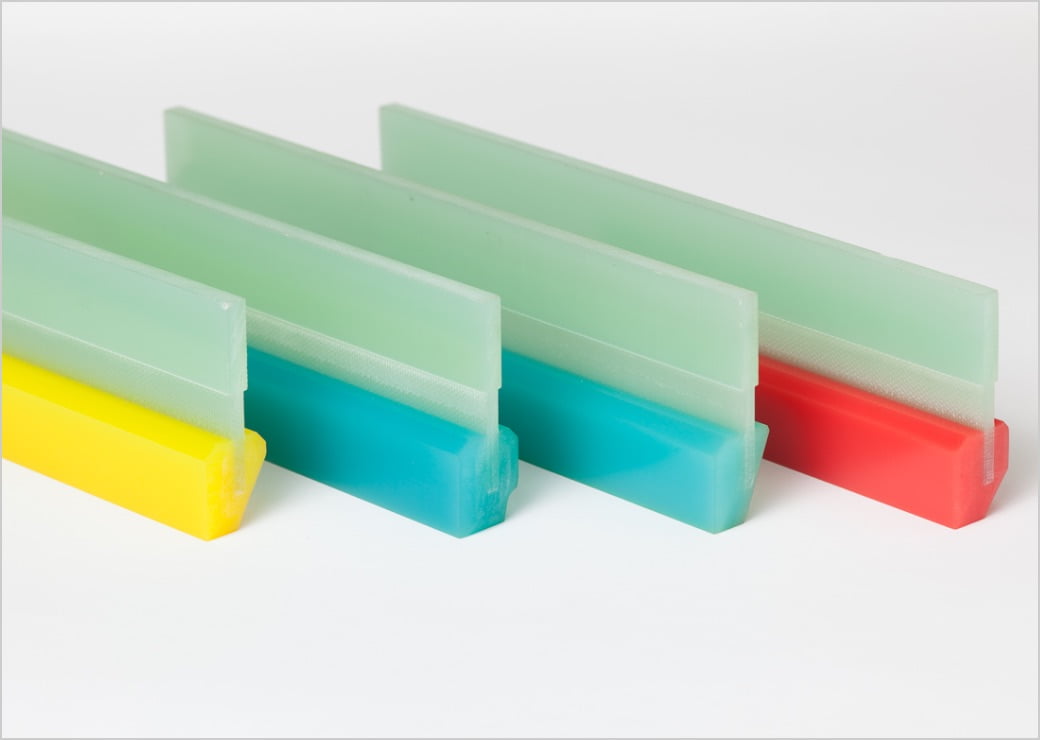

Micro squeegee

Features

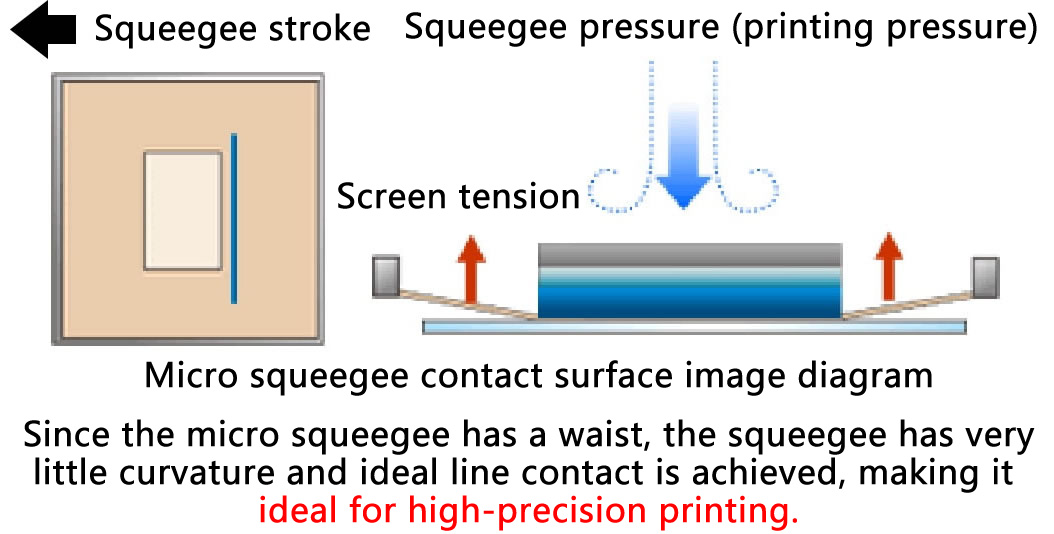

The decisive factor for screen printing is the squeegee. It is important to keep the attack angle constant in order to obtain stable print results. The Micro squeegee has a composite structure of urethane rubber (also silicon rubber) and a glass epoxy core material, and the weight of the squeegee head can be reduced, making it an ideal squeegee for practicing the proper printing process.

It has excellent polishing resistance and a sharp polished surface can be obtained.

The attack angle can be kept constant due to the composite structure with the glass epoxy core material.

There is little bending and deformation, and uniform printing is possible with stable printing pressure.

If you use S80, it can also be used for γ-butyl lactone.

We have 4 types to suit your needs.

(If you use the Micro DB Squeegee Series, the squeegee itself has an angle or radius, so stable paste rolling can be obtained.)

Various Micro squeegees / Micro silicon squeegee specifications

| Type | Micro squeegee | Micro silicon squeegee | ||||

|---|---|---|---|---|---|---|

| Hardness | Y60 | B70 | R80 | S80 | ||

| 60°±5° | 70°±5° | 80°±5° | 80°±5° | |||

| Cut size tolerance | ±2mm | ±2mm | ||||

| Angle polishing | From 70 ° to 90, angle polishing is possible every 5 ° | |||||

| Longest dimension | 550mm | 400mm | ||||

DB squeegee/DB-R squeegee specifications

| Type | DB squeegee | DB-R squeegee | ||||

|---|---|---|---|---|---|---|

| Hardness | Y60 | B70 | R80 | Y60 | B70 | R80 |

| 60°±5° | 70°±5° | 80°±5° | 60°±5° | 70°±5° | 80°±5° | |

| Cut size tolerance | ±2mm | ±2mm | ||||

| Angle polishing | every 5 ° | Not possible | ||||

| Longest dimension | 1500mm | 1000mm | ||||

Ability of Micro squeegee

A glass epoxy material is used for the core material of the squeegee, and the squeegee has a waist, so a stable attack angle can be maintained. In addition, it is easy to put on and take off because it does not require a squeegee holder.

We accept various options and modifications

according to the application and budget.

Please feel free to contact us

about screen printing machines.