Solar wafer (Crystalline Sillicon)

Equipment for this application

MT-650 seriesIt is a printer that is not only reliable but also easy to use

Various fully automated print linesWe can offer automated lines suitable for your application

About crystalline sillicon solar wafer

Among the many types of solar cells, crystalline Solar cells have a good efficiency performance and they are the type with the highest share in the market.

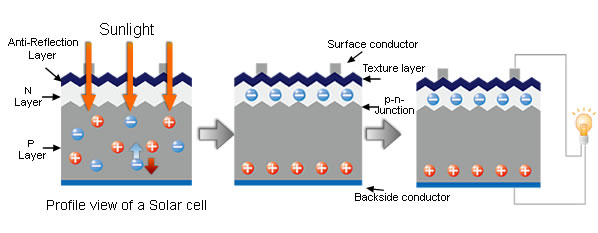

The principle of energy generation of crystalline Solar cells

The sunlight that shines on a solar cell looses positive and negative electrons, which start to move inside the cell.

When the negative electrons touch the p-n-junction and move in the n-layer, the positive electrons stay in the p-layer.

Both are separated from each other and electric voltage starts to flow.

Touching the surface conductors, an electric current is produced and electricity generated. Screen-printing can be used especially for applying the surface conductors on the silicon wafers.

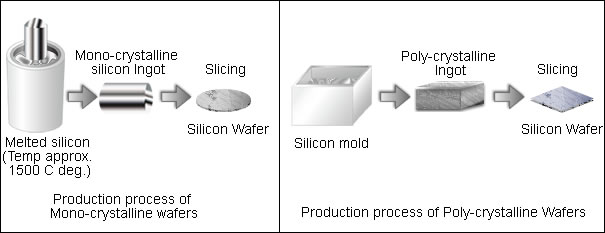

Differences between mono-crystalline and poly-crystalline silicon wafers

Crystalline silicon solar cells consist of two types: mono-crystalline cells and poly-crystalline cells.

The basic principle is nearly the same; both types are produced from a silicon ingot but every type has its advantages and deficits, regarding cost and cell quality.

| Advantages and deficits of Mono-crystalline Solar cells | Advantages and deficits of Poly-crystalline Solar cells |

| Advantage: Higher energy efficiency | Advantage: Production cost lower because of low raw material price |

| Deficit: Production cost high because of high raw material price |

Deficit: Energy efficiency is lower because of low-quality silicon structure |

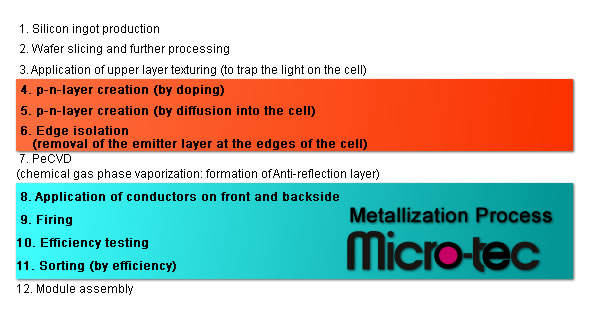

Basic process of Solar cell production in combination with the Screen-printing method

Achieving a higher efficiency … Micro-tec’s solutions

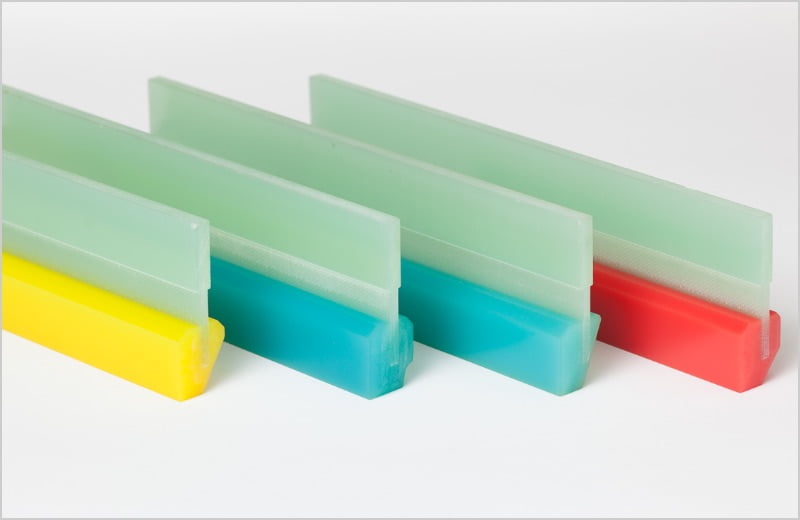

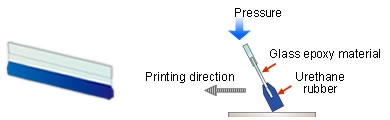

Micro Squeegee

With Micro-tec’s original squeegee, it is possible to print high performance conductive lines on a stable level.

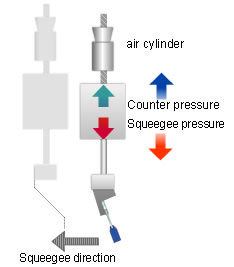

Air-Balance

This original pressure control mechanism minimizes the stress on the wafer for a low breakage rate.

Furthermore the damage to the texture layer of the wafer is also minimized.

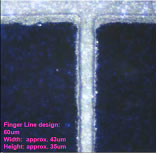

Multi-layer printing of high-aspect conductors

Micro-tec screen printers with high-precision alignment system are also capable of multi-layer print (high-aspect finger line print).

Equipment for this application

MT-650 seriesIt is a printer that is not only reliable but also easy to use

Various fully automated print linesWe can offer automated lines suitable for your application

We accept various options and modifications

according to the application and budget.

Please feel free to contact us

about screen printing machines.